-

Phone

86-757-85436831

-

Address

National Eco-Industrial Park, Danzao, Nanhai, Foshan, Guangdong, China

-

E-mail

LatestProducts

High Speed Plastic Packaging Automatic Vacum Forming Machine

China High Speed Plastic Packaging Automatic Vacum Forming Machine, Find details about China Forming Machine, Vacum Forming Machine from High Speed Plastic Packaging Automatic Vacum Forming Machine - Honggang Cutting Machine Co., Ltd.

Description

Basic Info

- Model NO.: HG-DGD850

- Column number: Four Column

- Automatic Grade: Automatic

- Application: Plastic Cups/Boxes/Plates/Containers

- Forming Area: 710*850*120mm

- Heat Furnace Size: 7800*2600mm(Top+Bottom)

- Trademark: honggang

- Specification: 11000*2300*2600mm

- HS Code: 8401200000

- Certification: CE

- Molding Method: Pressing

- Warranty: 1 Years

- Suitable Sheet: PP, BOPS, PE, PVC, Pet, ABS, HIPS, EPS etc.

- Forming Speed: 12-20 Stroke/Minute

- Mold: Forming Mold and Cutting Mold

- Transport Package: Standard Export Wooden Case Packing

- Origin: China

Product Description

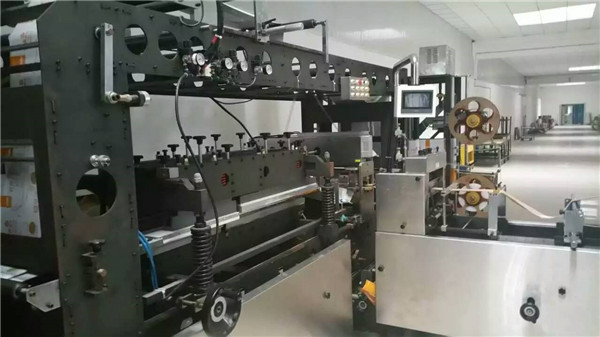

high speed plastic packaging automatic vacum forming machine

1. application

This plastic cup thermoforming machine used for producting high demand of disposable fresh/fast food,fruit plastic cups,boxex,plates,container,and pharmaceutical,wine,electrical blister packaging,PP,PS,PET,PVC,OPS plastic sheet etc.

2. Features and Advantages

1. Fully servo driven machine.no noise.no vibration,forming good and fast.

2. Fully machine in compact structure,taking small floor space;

3. Can be adapted to a variety of materials,and the products thicker 8% than the average machine products.

4. Furnaces automatic removal device,can be turned down at any time during production without breaking the sheet.reaching without wasting materials;

5. Electric furnace temperature control system uses intelligent automatic compensation control,a control,a control of a regulator,easy to adjust the temperature uniformity,easy to use,simple,fast heating,low temperature three times up and down the oven roast slices.

6. Forming,cutting die servo-driven,two-way adjustable for upper and lower mold stroke,in which the upper mold electric adjustable in clamping direction. The upper and bwer molds height position can be adjusted conveniently and fast under the clamping state;lower mold in clamping direction readily accessible buffer,increasing the clamping speed,avoiding shock.

7. Auto cutting,auto counting,auto transmission by PLC.

8. Labor saving,only 1-2 workers packing.

3. Main function

1.positive and negative pressure forming device.

2.vacuum forming device.

3.touch screen computer temperature module point to point control function.

4.air control device.

5.cooling device.

6.die, mold temperature control function.

7.automatic punching and cutting function.

8.automatic stack counting function.

9.edge automatic rewinding function.

10.safety protection device.

4. Specification

1. application

This plastic cup thermoforming machine used for producting high demand of disposable fresh/fast food,fruit plastic cups,boxex,plates,container,and pharmaceutical,wine,electrical blister packaging,PP,PS,PET,PVC,OPS plastic sheet etc.

2. Features and Advantages

1. Fully servo driven machine.no noise.no vibration,forming good and fast.

2. Fully machine in compact structure,taking small floor space;

3. Can be adapted to a variety of materials,and the products thicker 8% than the average machine products.

4. Furnaces automatic removal device,can be turned down at any time during production without breaking the sheet.reaching without wasting materials;

5. Electric furnace temperature control system uses intelligent automatic compensation control,a control,a control of a regulator,easy to adjust the temperature uniformity,easy to use,simple,fast heating,low temperature three times up and down the oven roast slices.

6. Forming,cutting die servo-driven,two-way adjustable for upper and lower mold stroke,in which the upper mold electric adjustable in clamping direction. The upper and bwer molds height position can be adjusted conveniently and fast under the clamping state;lower mold in clamping direction readily accessible buffer,increasing the clamping speed,avoiding shock.

7. Auto cutting,auto counting,auto transmission by PLC.

8. Labor saving,only 1-2 workers packing.

3. Main function

1.positive and negative pressure forming device.

2.vacuum forming device.

3.touch screen computer temperature module point to point control function.

4.air control device.

5.cooling device.

6.die, mold temperature control function.

7.automatic punching and cutting function.

8.automatic stack counting function.

9.edge automatic rewinding function.

10.safety protection device.

4. Specification

| specification: | |

| Forming area: | 710×850×130 mm (W*L*H) |

| Forming speed: | 12-20 stroke/minute |

| Machine size: | 11000×2300×2600 mm (L*W*H) |

| Heat Furnace size: | 7800×2600 mm (Three pieces ofbaking sheet) |

| configuration: | |

| Pulling: | Delta servo driver |

| temperature control: | Delta temperature controlling moduls |

| Oil pump: | Germany Rexroth |

| Oil valve: | Germany Rexroth |

| Circuit: | Japan Fuji |

| Touch screen: | Delta |

| Transmission: | Imported from Japan |

| Electric control: | Delta,IDEC |

| Vacuum system: | Germany imported vacuum pump |